1.Electronics Production

Group assignment

Machines-Roland modela MDX-20

Our fablab has Roland mdx-20

The Roland Modela MDX-20 is a small milling machine and a 2 1/2D precision scanner. This machine is mostly used for milling circuit boards, though it can also mill in other soft materials like machinable wax. For milling circuit boards you should export you design into a black&white monocroome png. For milling out 3 dimensional molds you should export your design as .stl The second use of this machine is scanning. It uses a thin needle to gently touch the object and calculates from this a 2 and a half dimensional model. Though slow at processing, it can create high detailed model. Work area: 203 x 152 x 60 mm (directly picked from wikipidia)

2.milling bits

We have two different bits to work with our PCBs. 1/64” - Used for milling the trails on the board 1/32” - Used for drilling holes and cutting the board

3.Softwares

Our instructors recommended us to test the machines generating files from two different softwares: MODS and Fab Modules. The one that i preferred most is the fab modules which wasnt straigh forwared but i got the gist of it.

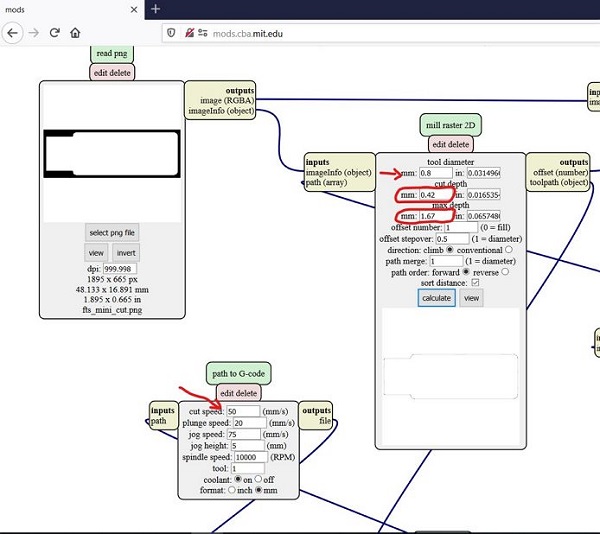

the following is how is set up my mods for cutting using the via modela

the process of milling showed up to being defficult on setting up the modela and time was running out

having been familiar with the fabmodules i went ahead and generated the following for my programmer

.png)

still configuring modela roland MDX-20

After the failure to configure modela my only other option was to use chemical method which i tried as much as i could to avoid

This is the chemicals bought for the process:

the etchants were mixed in the ratio of 2:1 repspectively

after downloading the files i continued to etching

the final etched board looked as follows

>

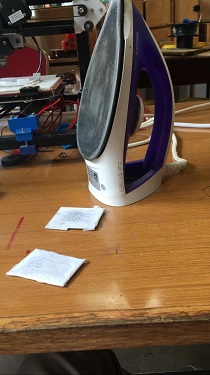

You might be wondering how i transffered the traces to the board, i used the iron boxto transfer them

Obtain the components:

I decided to end the production here and since there was production of the same in week six and try to use modela to do the milling of the pcd

6.Programming

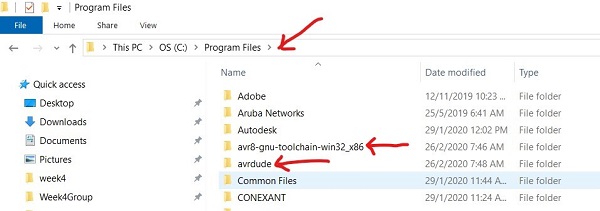

The last bit was to program the ISP to be ISP itself. I used Avrdude to do this following tutorials provided. i decicided to push this to week 6 since of the problem experincing below

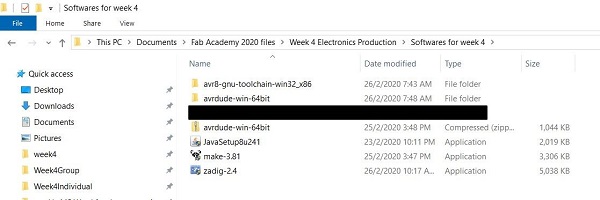

for this week i decided to download and keep the files ready following closely how my fellow students managed to do it

this is by downloading the software for ATtiny45

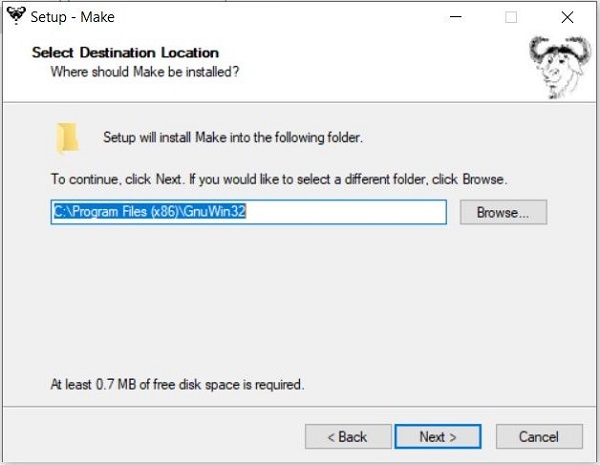

and setting it up

i decided to push to week six and set up the modela

7.Problem experiencing

you can get the files here

Design FileProblem facing